- Home

-

Products

Screw Air Compressor

Air Conditioning Heat Pump

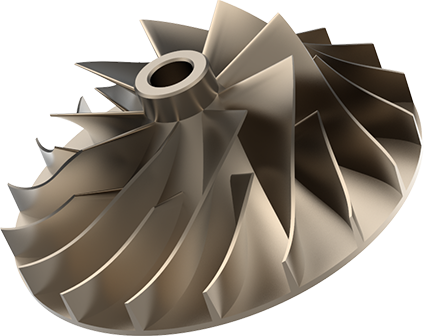

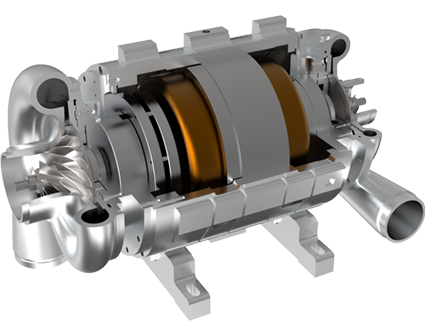

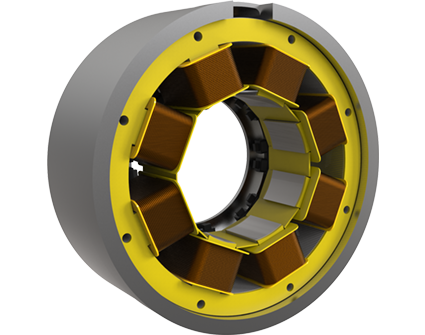

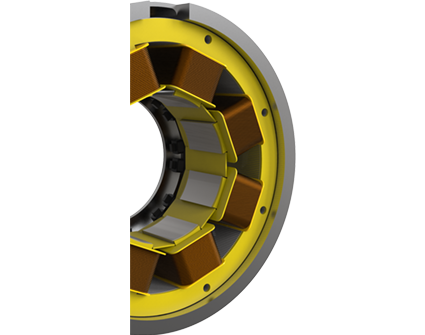

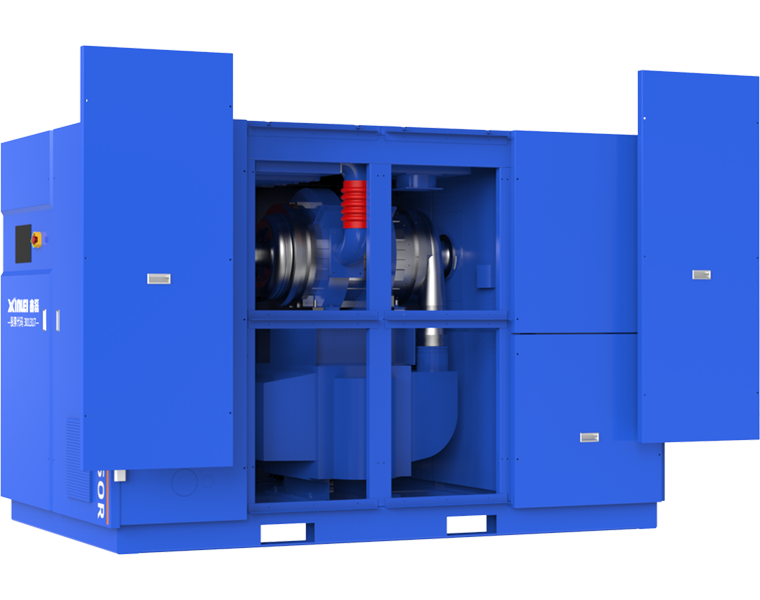

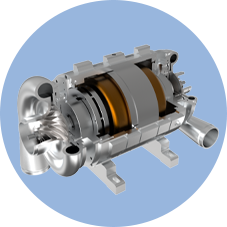

High-Speed Permanent Magnet Centrifugal

Car-Mounted Air Compressor

Piston Air Compressor

Oil Cooling Series

There is currently no relevant data available!

There is currently no relevant data available!

There is currently no relevant data available!

-

Solution

- Research&Development

- Intelligent Manufacturing

- News

- Career

- Service&Support

- About